Description

Globe valve uses a disc-type/plug, which is always in the path of the flow, to regulate the flow volume; this process is called throttling.

A Globe can also be used as a stop valve (for starting and stopping flow).

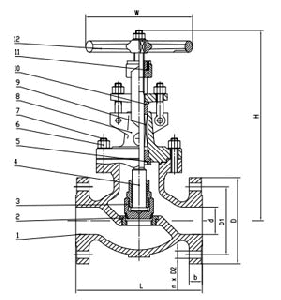

Globe valves are generally characterized for their spherical body with the two halves of the body being separated by an internal baffle.This has an opening that forms a seat onto which the disc, connected to a stem, can be screwed in (if operated manually) or slid in (if automated) to close the valve.

However many globe valve designs do not have the traditional round body-shape. Still, valves that contain the same mechanism are referred to as Globe valves.

Globe valves have several types of designs: globe, angle, Y-pattern, T-pattern, control, etc.

Application

A complete range of globe valves, ideal for throttling and shut off services for oil & gas, petrochemical, power, offshore and other demanding applications. Designed for duties where high flow efficiency, tight shut-off and long service life is a prime requirement. A wide choice of shell and trim materials do cover the whole range of applications, from the every-day type of non-corrosive service to critical service with highly aggressive media.

Constructive and functional characteristics

- type: bolted bonnet, outside screw and yoke

- flexible wedge

- rising stem with top sealing (backseat)

- full bore

- flanged ends

- shutting-off: by rotating the handwheel in clockwise direction

- mounting position: any

Execution

- basic design according to BS 1873

- face to face according to ANSI B16.10

- flanges according to ANSI B16.5

- flange facings: 0,06″ raised face;

- pressure – temperature ratings according to ASME B16.34

- shell wall thickness according to BS 1873

- testing according to API 598

- trim standard: no. 1 main sealing 13% Cr / 13% Cr.

On request

- other basic design according to BS 1873

- other shell materials (Carbon steel, Stainless steel, Monel, Duplex, Inconel)

- other trim

- other flange facings according to ANSI B 16.5 or B/W ends to ANSI B16.25

- other type gasket body – bonnet

- lantern ring for class 300

- drain tappings

- by-pass

- open and shut indicator

- electric actuator operation

- manufactured according to specification NACE MR 0175 for hydrogen sulphide and sour gas service