Description

|

|

|

- Maxiflex spiral wound sealing element

- Wide choice of materials for filler and metal strip

- Suitable for high pressure and temperature applications

- Recommended flanges -tongue and groove, male to female and flat face to recess

- General and critical duties

|

- Maxiflex spiral wound sealing element

- Solid metal outer ring used as centering device and compression stop

- Used mainly on raised face and flat face flanges

- General duties

|

- Maxiflex spiral wound sealing element

- Solid metal inner ring

- High pressure temperature capability

- Male to female flanges

- General and critical duties

|

|

|

|

|

|

|

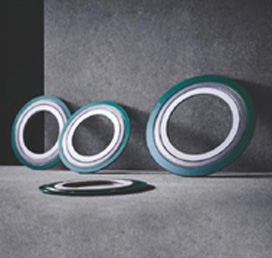

- Maxiflex spiral wound sealing element

- Solid metal inner and outer ring

- Suitable for high pressure and temperature applications

- Raised face or flat face flanges

- Prevents turbulence and erosion damage to flange

- Prevents damage to the gasket bore and inner windings

- Acts as a heat shield

- Acts as a corrosion barrie

- General and critical duties

|

- Maxiflex spiral wound sealing element

- Solid PTFE inner ring solid metal outer ring

- Raised face or flat face flanges

- Acts as a secondary seal

- Environmentally friendly

- Corrosion barrie

|

- Maxiflex spiral wound sealing element

- Solid metal Graflex covered inner

- Suitable for high pressure and temperature applications

- Raised face or flat face flanges

- Corrosive media

- Acts as a secondary seal

|

|

|

|

|

|

|

- Maxiflex spiral wound sealing element.

- Wound high density

- Wide choice of materials for filler and metal strip

- High pressure pumps

- High pressure valves (Gas service)

- Gas service

- Low emission tested

|

- Maxiflex sealing element

- Covered with 0.5mm Graflex

- Used on Manhole covers

- Low bolt load applications

- Uneven sealing faces

- Double integrity seal

|

- Maxiflex spiral wound sealing element

- A combination of inner and outer rings

- The inner ring could have pass bars or could carry either a metal clad or soft gasket with pass bars

- Manufactured to customer designs

|

|

Technical Details

Metal Strip Material

| Stainless Steel 316L, 316, 316TIC, 304, 321, 310, 347 Duplex

|

| Titanium, Hastelloy/lncoloy 800, 825 |

|

Filler Materials

|

Temperature Units

|

|

|

Special Canadian Asbestos

|

550° C |

|

|

|

|

|

|

|

|

Nonas (Asbestos Free)

|

460° C |

|

| *3000 C in reducing atmospheres |

Recommended Flanges Surface Finish

Recommended Flanges Surface Finish Maxiflex gaskets are capable of giving an excellent seal over a wide range of flange surface finishes, but as a general guide we offer the following:

|

General

|

125 – 200 |

3.2 – 5.1 |

Gasket Compression and Choice of Thickness

Gasket Nominal

Thickness |

Recommended Compressed

Thickness |

|

Centering | and Inner | Ring Standard Materials

|

|

|

Carbon Steel Zinc Plated with Chrome Passivate

|

|

|

Stainless Stee1316, 304, 410, 316L, 316TI, Duplex

|

|

|

|

|

Titanium Inconel 600, 625

|

|

|

Standard Thickness 3.2mm

|

|

Flange Suitability

|

| BS1560 and ANSI 816.5 1/2 ” – 24″ 150-25001bs |

| BS10 Tables D – T |

| B450410-250 Bar |

| MSS SP 44 26″ – 60″ 150 – 900 lbs |

| API 605 26″ – 60″ 150 900lbs |

| DIN |

Important notes :

- These figures are not complete and refer to one type of carbon steel only. Consult ANSIBI 16.5 for full detail.

- Other standard flanges (eg. DIN, BS10, BS4504) similarly have temperature/pressure rating listed.

The following giudelines reflect common custom and practice for sizes 1/2(half)” – 24″ inclusive :-

Notes :

- Not exceeding 10 bar pressure and usually for liquids only.

- We recommend 1.5mm gasket thickness for Class 150 and 1.0mm for Class 300.

- We recommend that inner and outer retaining rings also be fitted i.e., Maxiflexiflex Type CRIR with zinc plated carbon steel outer ring, stainless steel 316L metal winding, “Graflex” graphite filler winding and stainless steel 316 inner ring. Initial thickness of winding 4.5 mm (compressed thickness 3.2 to 3.4 mm).

- Can be used to this Class rating but suitability depends on operating temperature, pressure and media.